PRECISE CUTTING TECHNOLOGY FOR HIGH DEMANDS

Automated hose and cable production for wind turbines

Metzner has been impressing turbine manufacturers with its automation technology for as long as there have been wind turbines. Metzner offers a wide range of machines for cutting hoses, which have to meet special requirements in terms of temperature resistance and material quality due to their use. It makes no difference whether you want to automatically cut hoses for gearbox cooling systems, hydraulic brake systems, rotor blade adjustment or any other part of the wind turbine.

Secondly, the Metzner AM 5000 models and the Ramatech Speedy enable automated processing of the cables required in wind turbines. Metzner is your competent partner with many years of industry experience in both areas.

Machines for the processing of hoses and tubes

One machine - 10,000 combination possibilities

The universal cutting machines ST-OB and Variocut can, as the name suggests, cut various materials to the right size. They differ fundamentally in terms of operation. The Variocut impresses with its simple operation and automated process, in which the material is always fed to the blade with the same pneumatic pressured.

The ST-OB, on the other hand, is always the right choice when the operator needs to make fine adjustments. The pressure can be set precisely using a rotary knob. The skilled operator can even react to slight differences in the material batches.

Maschinen zur Kabelverarbeitung

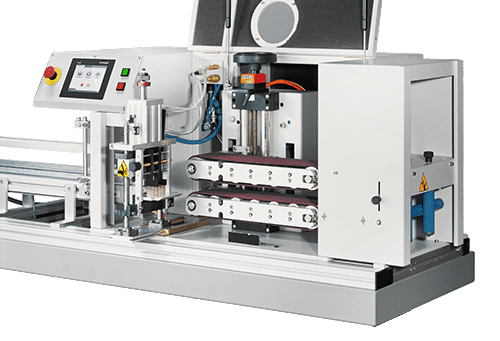

The Metzner AM 5000 range is designed for cables up to 35 mm | 1.38″ diameter and 185 mm² | 350 MCM cross section, the Ramatech Speedy Models, on the other hand, can cut and strip diameters up to 40 mm | 1.57″ and cross-sections up to 400 mm² | 750 MCM.

Both the Metzner AM 5800 and the Metzner AM 5850 with rotary cutting head impress with their complete software equipment as standard and the double blade cutting system, for more versatility in one pass. Both models are also designed for a cutting force of up to 185 mm² as standard. There are no additional costs.

Cutting power up to 400 mm² | 750 MCM

The Speedy was specially developed by our sister company Ramatech for cables that are difficult to process. Thanks to the hydraulic cutting unit, cables with a high copper content can be cut and stripped just as easily as cross-sections up to 400 mm² | 750 MCM. Naturally, suitable printers and peripherals are available for both models. .