AUTOMATION OF CONTROL CABINET CONSTRUCTION

From CAD data automatically to the cables. Best solutions for the control cabinet construction

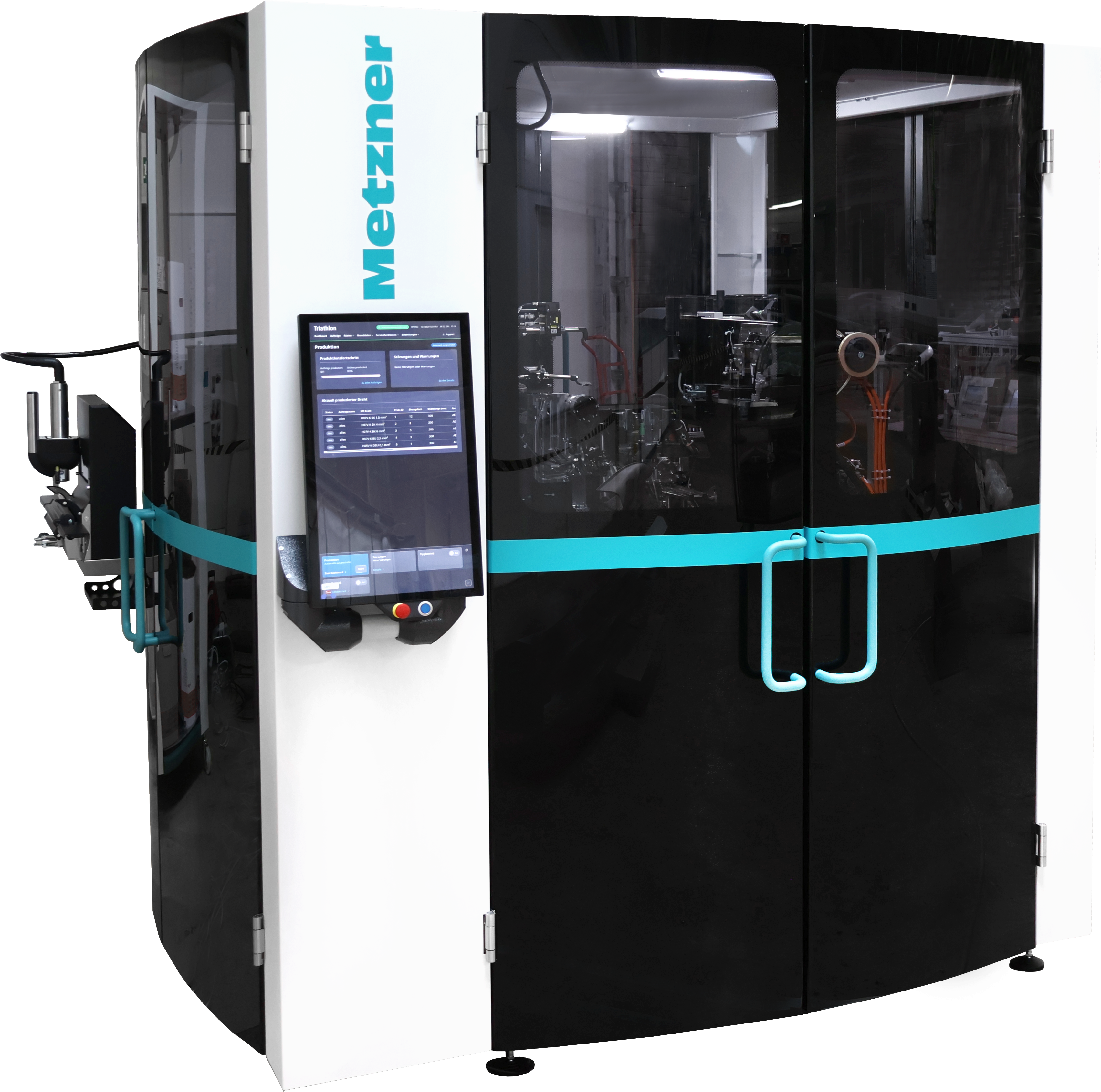

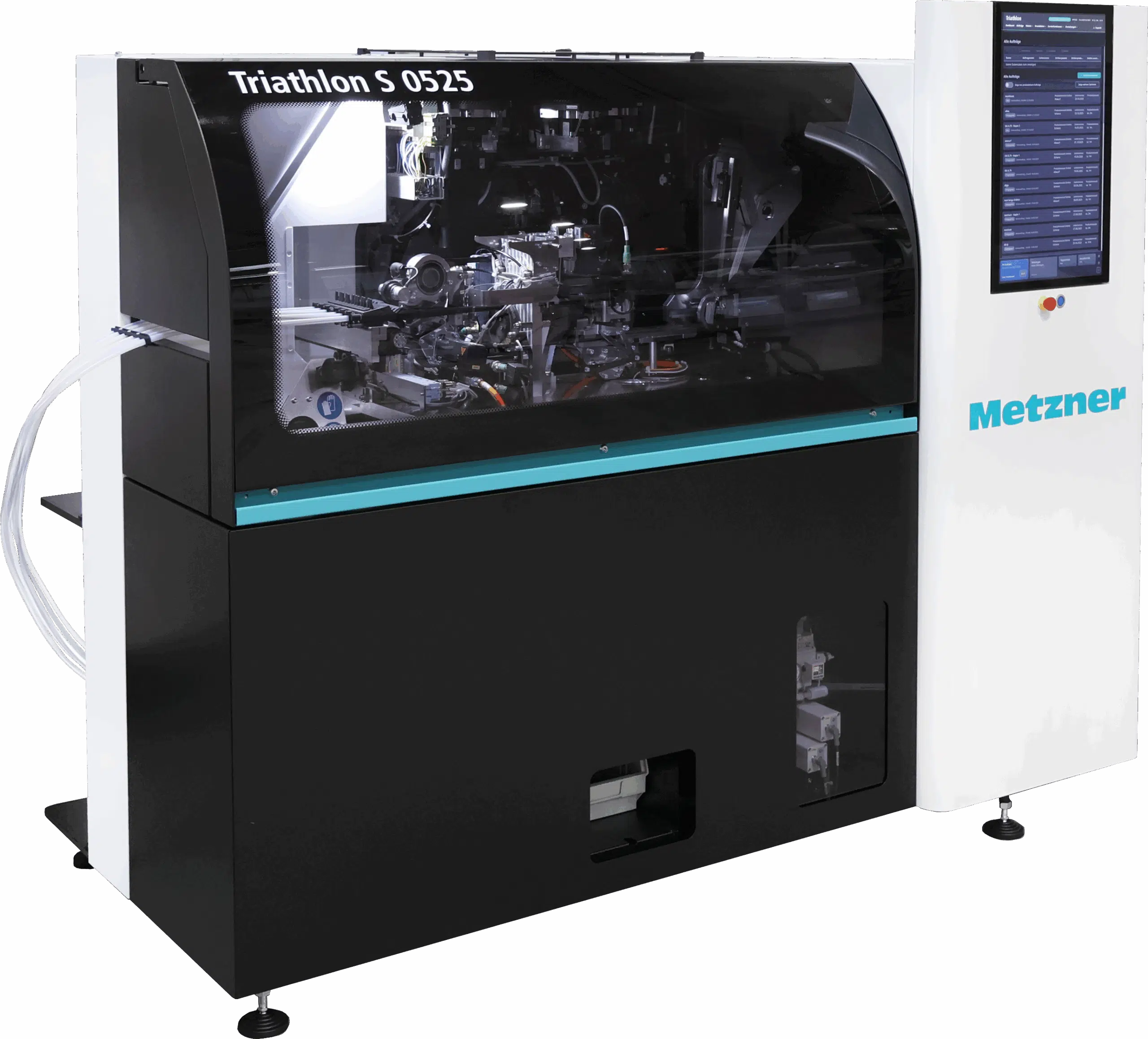

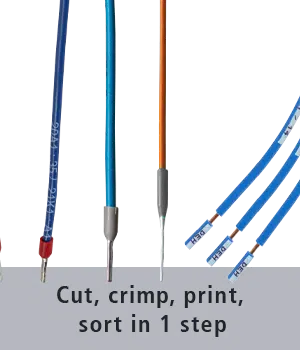

If control cabinet construction is part of your production, you should take a closer look at Triathlon. Triathlon 3000 as well as Triathon 3000 + automate the production process. Based on the CAD data, the machine cuts your cables to length, strips them, prints them and sorts them. Printing can be done in black and white or color. It is also possible to print a white surface, which is then inscribed in black.

With the Triathlon series, you can easily automate your control cabinet construction and production. After importing the CAD data into Triathlon, the control cabinet is designed. The software collects the wiring, assembly or terminal lists and all other necessary data. It then automatically creates the data for mechanical processing and delivers it to the Triathlon machine.

Processing includes cutting as well as stripping on one or both sides. Crimping and printing with up to two printers as well as pre-sorting the cables are also part of this automatic enclosure production process. The Triathlon can print in either one or several colors. It is also possible to print a white area, which is then labeled black on white by the Triathlon.