METZNER SM 4000: A UNIQUE SOLUTION - WOLRDWIDE

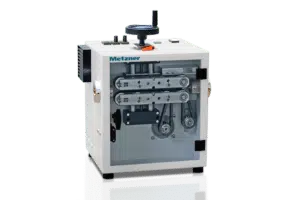

The SM 4000 cutting machine for pre-slit corrugated tubes

The Metzner SM 4000 is unique in the world, since it cuts pre-slit corrugated tubes

8,000 cuts per hour

The extremely flexible material is guided to the blade by means of a specific feed. A laser checks the cutting position so that the cut is made cleanly at the desired location.

This machine is unique in the world, because the patented Metzner SM 4000 cutting machine cuts pre-slit corrugated tubes and hoses. This extremely flexible material is brought into the correct shape with the help of a precise transport system. When it is transported to the cutter, a laser sensor controls the position of the feed wheels. This ensures that the cut is made exactly at the required point.

APPLICATIONS

The Metzner SM 4000 cuts pre-slit corrugated tubes. Thanks to its patented system, the blade cuts precisely on the crest – up to 8,000 times per hour.

TECHNICAL DATA

| Technical Data | SM 4000 |

| Corrugated tube diameter max. (depending on material) | 40 mm | 0.18″ |

| Feeding speed (max.) | 160 m/min. | 525 ft./min. |

| Electrical connection | 230 V; 50/60 Hz; 1.2 A or transformator |

| Power source | electro pneumatic |

| Compressed air connection | 6 bar | 87 PSI |

| Dimensions (L x W x H) | 597 mm x 807 mm x 595 mm | 3’11” x 3’10” x 4’7″ |

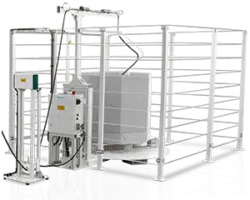

COMPATIBLE WITH:

the DHS loop control system and the Octabin feeding station