HIGH OUTPUT AND HIGH PRECISION SEALS-QUALITY

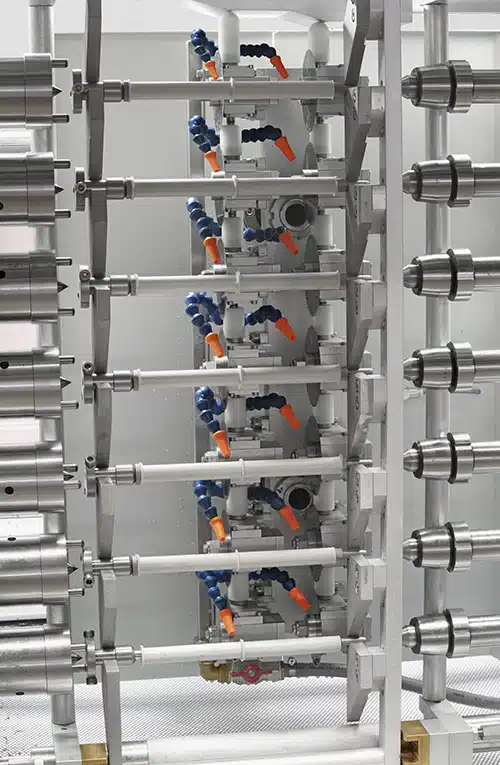

Precision mandrel cutting machines for the production of aerosol seals and precision gaskets

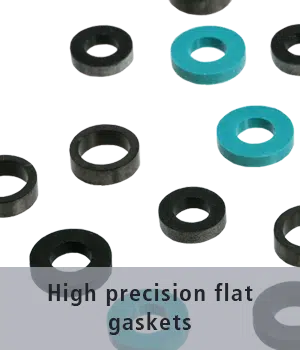

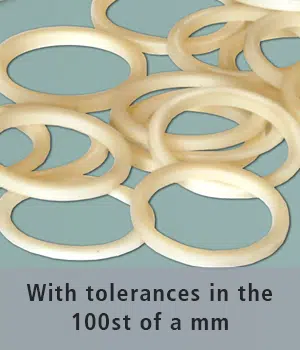

We have developed our Metzner SR 85 especially for the production of high-precision flat profile gaskets and seals from molded or extruded hoses. The production principle of this gasket cutting machine is simple and very fast. It also delivers the best quality results with tolerances in the hundredths of a millimeter range.

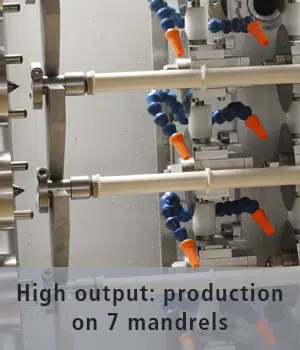

An operator, who does not need to have any specific experience, pulls the cut-to-length hose pieces over the specially developed mandrels. The machine then automatically clamps the mandrels in the rotation axis. A knife carrier then moves along the hoses and produces the seals with the help of a circular or piercing knife. High-precision flat gaskets are cut wet on 7 mandrels at the same time, with size increments of 0.01 mm | 0.0004″.

Size increments of 0.01 mm | 0.0004"

APPLICATIONS

Mass production of high-precision flat profile seals: Seals cut from molded or extruded tubes – e.g. seals for aerosol packaging, heat seals, chemical, gasoline and gas seals

TECHNICAL DATA

| Performance Data | Metzner SR 85 |

| Tube outer diameter max. | 85 mm | 3.3″ (7 tubes) 170 mm | 6.7″ (4 tubes) |

| Tube inner diameter max. | 20 mm | 0.8″ |

| Tube length max. | 540 mm |1’9″ |

| Distance between centers max. | 650 mm | 2’2″ (+/- 5 mm | 0.2″) |

| Number of tubes | 4 to 7 |

| Cutting rate max. (at cutting length 5 mm | 0.2″) | 4 x 100 cuts/min. 7 x 100 cuts/min. |

| Feeding | 0.3 mm to 100 mm | 0.01″ to 3.94″ |

| Size increments | 0.01 mm | 0.0004″ |

| Typical repeatable exactness (depending on material; tolerance +/- 0.5 mm | 0.02″) | +/- 0.2% |

| Reverse motion speed | 6 m/min. | 19’8″ m/min. |

| Tube rotation | 600 – 3,500 r/min. |

| Technical Data | Metzner SR 85 |

| Electrical connection | 3~400 V; 50/60 Hz; 25 A or transformator |

| Dimensions (L x W xH) | 2,800 mm x 1,320 mm x 1,900 mm | 9’2″ x 4’4″ x 6’2″ |

| Weight | 2,300 kg | 5,071 lbs |