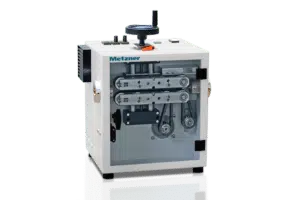

A MODULAR CUTTING MACHINE WITH 10k COMBINATIONS

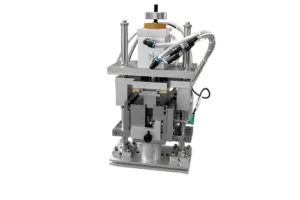

A serial machine that meets your needs exactly, that's the modular cutting machine Metzner MBS

You have the choice of 10 different cutting tools

100 mm or 200 mm or....

Combine your machine from standard components

You have the choice of 10 cutting technologies

Combine your machine from standard components

with integrated take-off system

The Metzner MBS is a truly modular cutting machine. In total, you can choose from more than 10,000 different possible combinations. The list of standard modules is therefore very long. On top, your specific requirements can also be adapted.

MOST COMMON CUTTING POSSIBILITIES

| Blade Cut | Draw Cut | Drilling | Eccentric Cut |

|  |  | |

| Draw cut with thin blades for high cutting quality | Drawing cut with knife, also with tensioned knife blade | Drilling in and through | Cuts at high working speed: up to 400 cuts per minute in start-stop mode |

| Hot Cut | Punch Cut | Shear Cut | Tool Cut |

|  |  |  |

| For braided hoses and similar materials | For precise miter cuts and 90° cuts | Used for glass fiber reinforced materials | Customized designs |

The table shows several examples. There are many more solutions. Furthermore, Metzner can realize customized tools and cutting solutions.

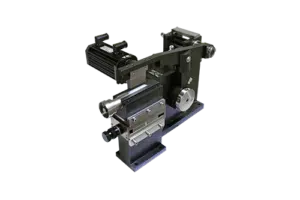

EXCHANGEABLE TOOLS

For your Metzner MBS, you can choose from more than 10 different cut types. What is more: You can also combine up to 3 in just 1 machine. So you can integrate more and different processing possibilities in just one automatic production run. Here you can see just 4 examples:

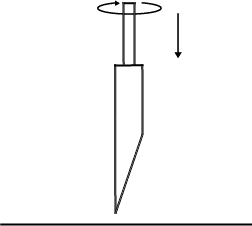

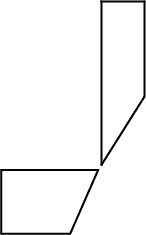

1st example:

Stam cut with automatic angle settings

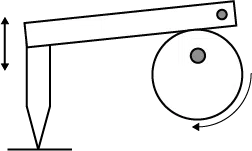

2nd example:

Tube cut with defined angle, defined knife profile, defined blade thickness and exact force

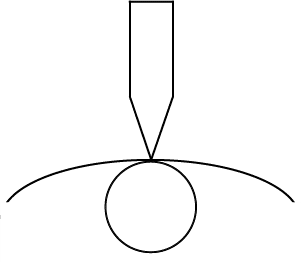

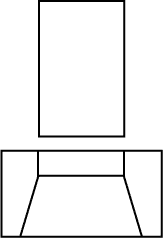

3rd example:

Contour cut tool, which offers concave and convex cuts as well as circular stamping in the middle of the material

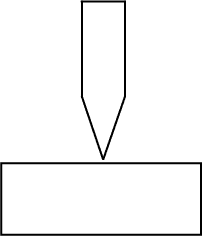

4th example:

Eccentric cut tool. It makes 400 cuts per minute, while the material is stopped before every cut. With electric drive instead of the unusal pneumatical one.

PERFORMANCE DATA

| Metzner MBS 100 | Metzner MBS 200 | Metzner MBS 400 | |

| Material dimension: width max. | 90 mm | 190 mm | 390 mm |

| Material dimension: height max. (Values are partly achieved with options only) |

30 mm – 80 mm |

30 mm – 80 mm |

30 mm – 80 mm |

| Size increments (Values are partly achieved only with options) |

60 m/min. – 150 m/min. |

60 m/min. – 150 m/min. |

60 m/min. – 120 m/min. |

| Cutting performance (with cutting length of 5 mm | 0.2″) |

170 cuts/min. | 130 cuts/min. | 60 cuts/min. |

| Length interval | 0.1 mm | 0.004″ | 0.1 mm | 0.004″ | 0.1 mm | 0.004″ |

| Typically repeatable exactness (Values are partly achieved with options only) |

+/- (1 mm + 0.2 % L) | +/- (1 mm + 0.2 % L) | +/- (1 mm + 0.2 % L) |

TECHNICAL DATA

| Performance data | Metzner MBS 100 | Metzner MBS 200 | Metzner MBS 400 |

| Compressed air connection | 6 bar | 6 bar | 6 bar |

| Dimensions (L x W x H) | Depending on the customized configuration | Depending on the customized configuration | Depending on the customized configuration |

| Weight | Depending on the customized configuration | Depending on the customized configuration | Depending on the customized configuration |

CONTACT US

When it comes to cutting and processing rubber or plastics, there is a MBS for every task. The modular cutting machine offers you more than 10,000 options. This is certainly sufficient to meet just about any cutting requirement. After all, the MBS can also cut or emboss contours. Please tell our specialist about your materials and cutting tasks, we will help you with a solution: