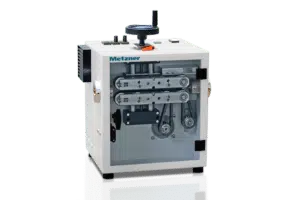

METZNER VARIOCUT UNIVERSAL CUTTING MACHINE

As variable as your cutting tasks and also very easy to operate

cuts rubber, cables, wire, plastics and much more.

no special knowledge necessary

which is secured with a password

The name says it all: with the Variocut universal cutting machine you can cut almost anything. It offers automatic variable cutting of profiles, pipes, tubes, plastics, foils, cables and wire. It is characterized by its easy handling as well as its high speed and reliability.

APPLICATIONS

The automatic variable cutting machine, the Metzner Variocut cuts many different materials. It is easy to operate because it works automatically without slippage of the material. Tool changes are also simple and tool-free.

TECHNICAL DATA

Feeding speed max.90 MPS

| Variocut | |

| Material dimensions: width max. | 65 mm | 2.6″ |

| Material dimensions: heigth max. | 30 mm | 1.2″ |

| Cutting rate/min. (at cutting length of 5 mm | 0.2″) | 140 |

| Typically repeatable exactness (depending on material; min. tolerance +/- 0.5 mm | 0.02″) | +/- (1mm | 0.04″ + 0.2% L) |

| Technical data | |

| Electrical connection | 230 V; 50/60 Hz; 10 A |

| Compressed air connection | 6 bar | 87 PSI |

| Dimensions (L x W x H) | 765 mm x 515 mm x 460 mm | 2′ 6″ x 1′ 8″ x 1’6″ |

| Equipment | |

| Controls | SPS |

| Control displays | 8 lines |

This automatic variable cutting machine is an excellent solution because it works at a speed of up to 140 cuts per minute. It is also suitable for materials up to 65 mm wide and 30 mm high.

The Variocut universal cutting machine also impresses with its extremely simple operation. Once the belt feed has been lowered, the material is automatically clamped. The pneumatic pressure prevents any slippage so that the operator does not have to adjust anything. Changing tools is just as easy, as the tools can simply be inserted and removed by hand. No adjustment is necessary. It can also be integrated into production lines and is available with punch, shear and draw cutting knives.

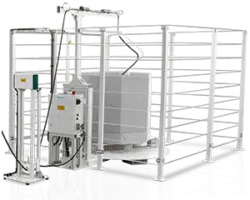

COMPATIBLE WITH:

the DHS loop control system and the Octabin feeding station for tubes